Packaging Machine Repair Service: Quick and Economical Solutions for Your Service

Packaging Machine Repair Service: Quick and Economical Solutions for Your Service

Blog Article

Comprehending the Key Parts and Repair Work Strategies for Product Packaging Machine Upkeep

Reliable upkeep of packaging makers rests on a detailed understanding of their crucial parts, consisting of the framework, drive system, and sealing devices. Recognizing typical upkeep problems, coupled with the implementation of preventative approaches and repairing techniques, can substantially improve equipment dependability. Additionally, the option of repair service methods, including using OEM components and the value of certified specialists, plays a vital duty in reducing downtime. To truly comprehend the details of these systems and their maintenance, one must think about the broader effects of overlooking these important practices.

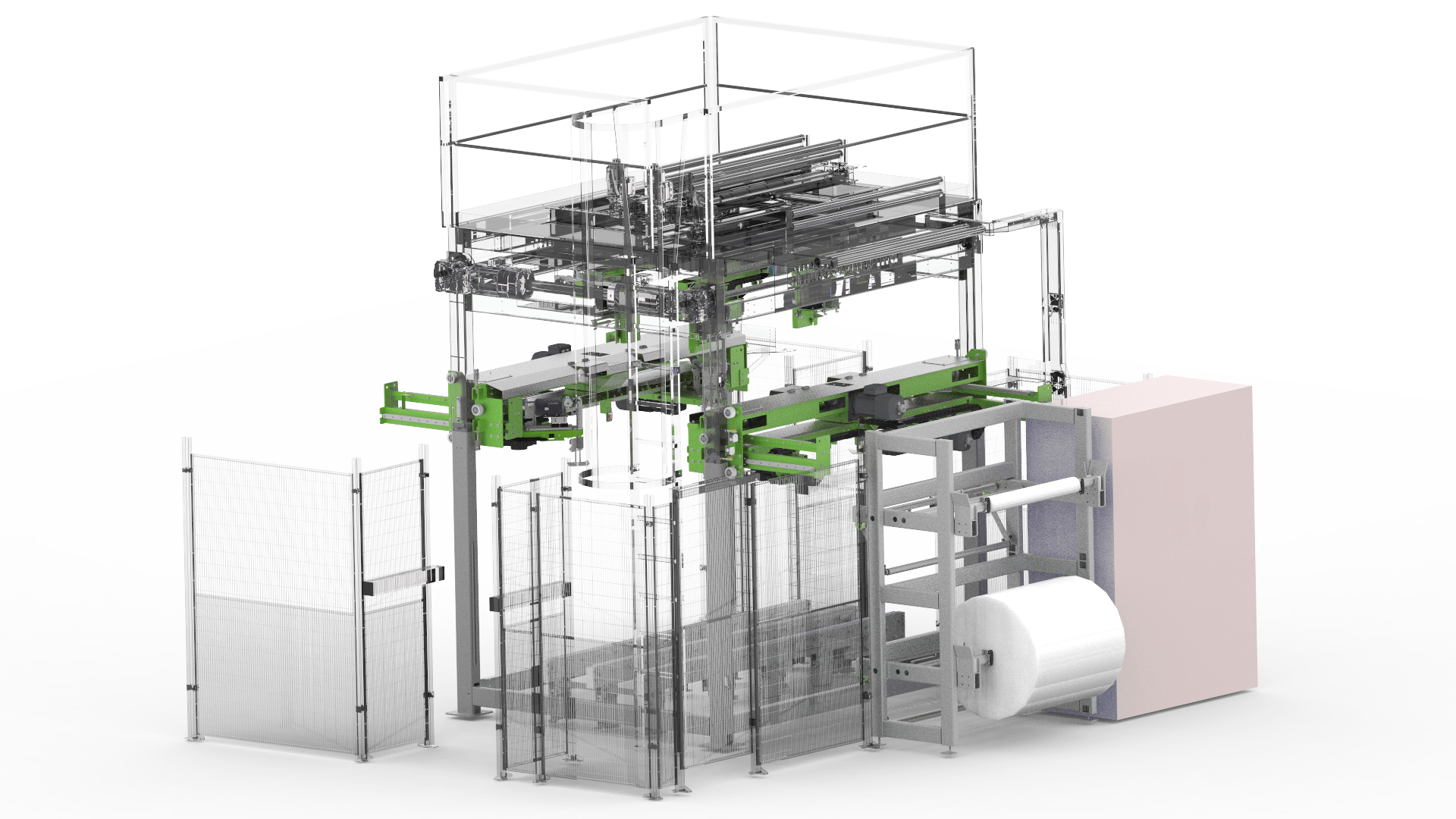

Secret Elements of Product Packaging Devices

Packaging makers contain numerous essential parts that collaborate to make sure efficient and reliable packaging processes. At the core of these devices is the frame, which gives structural honesty and houses the numerous operating components. The drive system, usually a combination of motors and gears, assists in the movement of elements, enabling precise procedure throughout the product packaging cycle.

An additional essential component is the conveyor system, which moves items through various phases of the packaging process. This is frequently matched by sensors and controls that keep an eye on the position and rate of products, making sure synchronization and reducing mistakes. The loading system is critical for properly giving the ideal amount of item into packages, whether in liquid, powder, or strong type.

Sealing mechanisms, consisting of warm sealers or adhesive applicators, play an important function in safeguarding bundles, protecting against contamination and expanding rack life. Additionally, identifying systems are indispensable for offering required product information, ensuring compliance with regulations. Ultimately, the control panel, equipped with easy to use user interfaces, enables operators to take care of machine features, screen efficiency, and make changes as required, making certain optimal productivity and effectiveness in product packaging procedures.

Common Maintenance Concerns

Reliable operation of product packaging devices relies heavily on regular maintenance to avoid common issues that can disrupt production. Amongst these concerns, mechanical damage prevails, specifically in elements like conveyors, electric motors, and seals, which can lead to unforeseen downtimes. Additionally, imbalance of components can lead to ineffective procedure, causing products to be incorrectly packaged or harmed during the process.

One more usual maintenance problem involves the build-up of dust and particles, which can disrupt the device's sensing units and relocating parts. packaging machine repair service. This not only affects performance but can likewise pose safety threats. Lubrication failings can lead to boosted rubbing, resulting in overheating and ultimate element failing.

Electric problems, often originating from loosened connections or worn-out circuitry, can interrupt equipment functions, resulting in considerable production delays. Software application problems due to incorrect arrangements or out-of-date programs can hinder the maker's procedure, requiring instant intervention. Resolving these usual upkeep issues proactively is necessary for guaranteeing ideal performance and durability of packaging machinery.

Preventative Maintenance Strategies

Implementing preventative maintenance methods is essential this for sustaining the performance and reliability of packaging devices. These methods incorporate a methodical approach to upkeep, concentrating on the regular evaluation and maintenance of tools to preempt potential failures. By adhering to a scheduled upkeep program, drivers can recognize deterioration on parts before they cause substantial break downs.

Crucial element of a preventative maintenance method include routine examinations, cleaning, part, and lubrication replacements based on manufacturer referrals. Making use of checklists can enhance this process, guaranteeing that no crucial tasks are forgotten. Additionally, maintaining precise records of maintenance tasks help in tracking the device's performance over time, facilitating educated decision-making relating to future upkeep demands.

Training team on the relevance of preventative upkeep enhances compliance and promotes a society of proactive care. Carrying out a predictive maintenance element, using data analytics and sensing unit modern technology, can even more enhance machinery performance by anticipating failures before they take place.

Troubleshooting Techniques

When faced with malfunctions or ineffectiveness in product packaging equipments, employing methodical troubleshooting strategies is vital for identifying and resolving concerns quickly. The very first step in efficient troubleshooting is to establish a clear understanding of the machine's functional specifications and efficiency metrics. This includes assessing the machine's requirements, as well as any kind of error informs or codes shown.

Following, drivers need to carry out a visual evaluation, inspecting for noticeable indications of imbalance, wear, or damages. This commonly includes taking a look at equipments, belts, and sensing units to determine potential causes of breakdown. Gathering functional data, such as production prices and downtime logs, can also provide insights right into reoccuring concerns.

As soon as prospective problems are identified, using a logical strategy to isolate the origin is essential. This may need testing individual parts or systems in a regulated way. Participating the original source in conversations with drivers who interact with the equipment on a regular basis can generate valuable responses regarding uncommon behaviors or patterns.

Fixing and Replacement Best Practices

A detailed understanding of repair work and replacement finest techniques is important for preserving the durability and effectiveness of packaging equipments. Regularly examining the condition of device elements enables prompt intervention, stopping even more significant concerns that can lead to expensive downtimes.

When fixings are necessary, it is essential to utilize OEM (Original Devices Maker) components to ensure compatibility and performance. This not just maintains the integrity of the device however also promotes warranty arrangements. Additionally, it is advisable to preserve a supply of crucial spare parts to assist in quick substitutes and lessen operational interruptions.

For intricate repair work, engaging qualified service technicians with specialized training in packaging machinery is recommended. They have the experience to identify issues accurately and perform repairs efficiently. In addition, documenting all fixing activities and components replacements is vital for preserving a comprehensive upkeep background, which can assist in future troubleshooting.

Finally, implementing an aggressive technique, consisting of regular evaluations and anticipating maintenance methods, enhances the integrity of product packaging makers. By sticking to these finest practices, companies can guarantee optimum machine performance, reduce operational threats, and prolong tools lifespan.

Conclusion

In final thought, a thorough understanding of product packaging device components and reliable upkeep approaches is vital for optimum performance. By implementing these practices, companies can guarantee the long life and performance of packaging makers, ultimately adding to boosted functional productivity and lowered costs (packaging machine repair service).

Efficient maintenance of packaging machines hinges on a complete understanding of their vital components, including the structure, drive system, and sealing systems.Reliable operation of packaging machines counts heavily on regular maintenance to prevent common issues that can interrupt production.Carrying out preventative maintenance strategies is critical for sustaining the performance and integrity of product packaging pop over to this web-site devices. In addition, maintaining accurate records of maintenance activities help in tracking the maker's performance over time, promoting educated decision-making relating to future upkeep requirements.

Report this page